How to Choose the Right CPQ & Visualization Tool for Your Manufacturing Tech Stack

Manufacturing companies looking to enhance their sales processes and customer experience are increasingly turning to Configure, Price, Quote (CPQ) solutions. However, choosing the right CPQ tool is no simple task—especially when visualization capabilities are part of the equation.

A recent guide from Logik.io, 50 Questions You Need to Ask in Your Next CPQ RFP (2025), outlines critical considerations to ensure that companies select a CPQ solution that is future-proof and adaptable to their evolving business needs. Below, we summarize key insights from the guide and provide additional commentary on why these considerations matter.

The CPQ Evolution: Why Traditional Tools No Longer Cut It

Many manufacturing companies are still using CPQ systems designed for simpler sales models of the past. Today’s business environment demands solutions that can handle complex configurations, multi-channel sales, and real-time visualization. A modern CPQ must support:

Customization & Flexibility – Adapting to unique business rules and product structures.

Omnichannel Capabilities – Supporting direct sales, distributors, and self-service models.

Data Integrity & Integration – Seamlessly connecting with ERP, MRP, and CRM systems.

Performance & Scalability – Handling large datasets and complex rules efficiently.

ROI & Future-Proofing – Ensuring the investment grows with the business needs.

Without these attributes, companies risk implementing a solution that quickly becomes outdated or fails to meet expectations.

Key Challenges When Evaluating CPQ Solutions

Based on the Logik.io guide, here are the most common pitfalls companies face when selecting a CPQ and visualization tool—and how to avoid them:

1. Configuration Engine: Attribute-Based vs. Product-Based

Some CPQ solutions focus on product-based configuration (predefined SKUs), while others use attribute-based configuration (customized options based on needs).

The best solutions offer both, allowing companies to serve different sales scenarios effectively.

2. Handling Complex Rules & Calculations

Many CPQ tools struggle with complex pricing structures, dependencies, and formulas.

Look for solutions with solving engines that optimize rule processing to prevent bottlenecks.

3. Visualization & Guided Selling

A good CPQ should support real-time visualization so that buyers can see what they are configuring.

Guided selling features help sales reps and customers make informed decisions with recommendation engines and compatibility alerts.

4. Integration with Back-End Systems

CPQ tools must pass configured data seamlessly to ERP, billing, and order management systems.

Without robust integration capabilities, businesses end up with data silos and manual workarounds.

5. Administrative Complexity & Ease of Use

Some CPQ solutions require specialized scripting languages, making them difficult to maintain.

The best tools provide low-code or no-code administrative interfaces, reducing IT overhead.

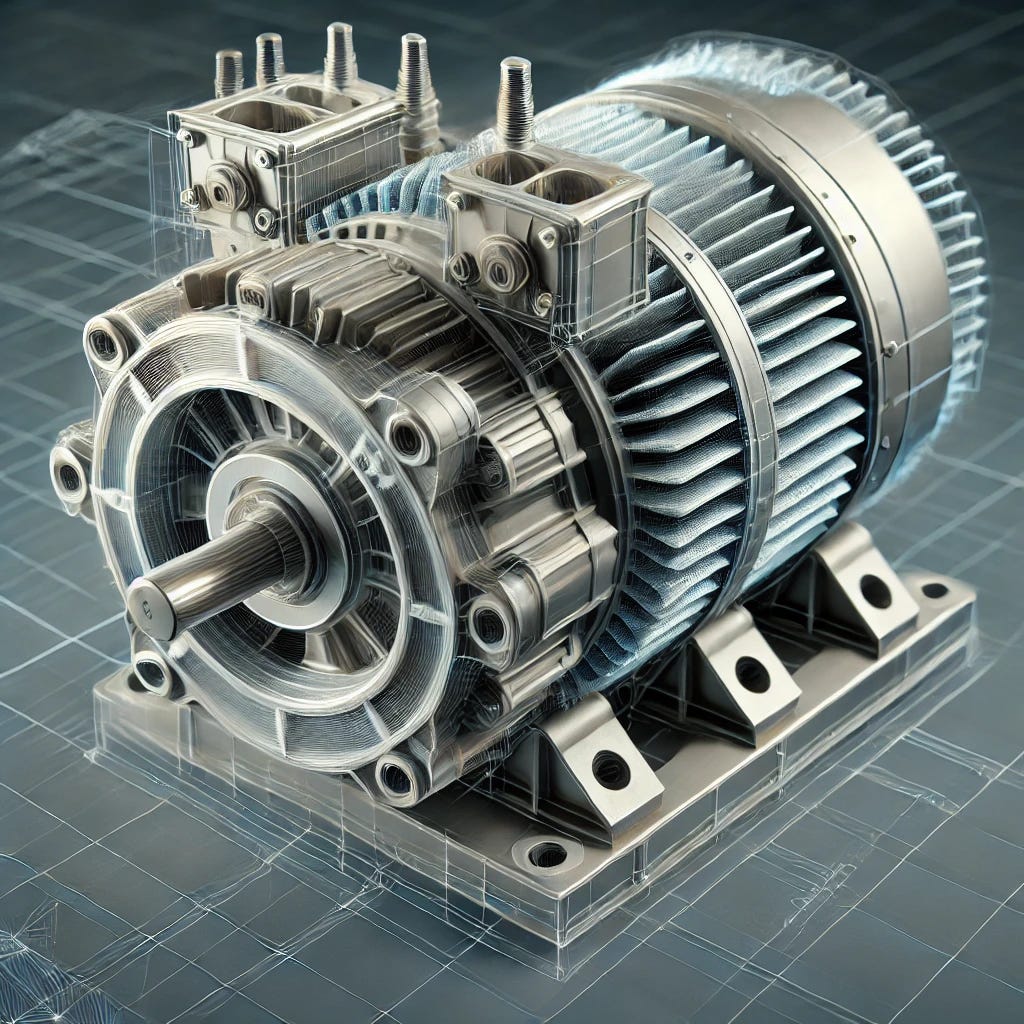

The Role of Visualization in CPQ

One of the biggest advancements in CPQ is the ability to visualize configurations in real-time. For manufacturing companies selling highly configurable products, visualization tools help:

Reduce errors by showing the customer exactly what they are configuring.

Speed up the sales cycle by eliminating the need for manual CAD drawings.

Enhance customer confidence, leading to higher conversion rates.

When evaluating CPQ solutions, manufacturers should ensure that visualization capabilities align with their product complexity and customer expectations.

Final Thoughts: Future-Proofing Your CPQ Investment

Choosing a CPQ and visualization tool is a strategic decision that impacts not just the sales process, but also engineering, manufacturing, and customer experience. As the Logik.io guide suggests, companies should rethink their RFP questions to ensure they are selecting a solution that meets their current needs and future growth.

By focusing on flexibility, integration, user experience, and visualization, manufacturers can implement a CPQ solution that drives efficiency and revenue growth while keeping pace with evolving market demands.

Looking to explore how CPQ and visualization tools can transform your sales process? Let’s discuss how to make the right choice for your manufacturing business.